ACCON AGLink

The fast and flexible communication library for smooth PC-PLC data exchange

- Library for PC-PLC communication

- For S7-200, S7-1200, S7-1500, S7-300, S7-400, S7-400H, LOGO! 0BA7 and 0BA8, S5 controllers

- For machine tool controllers SINUMERIK ONE, Create MyVirtual Machine, SINUMERIK 840D sl, 840D pl, 810D pl

- Via MPI, PROFIBUS, PPI, TCP/IP and RK512/3964(R)

- Supports all common programming languages via DLL or shared object and Java

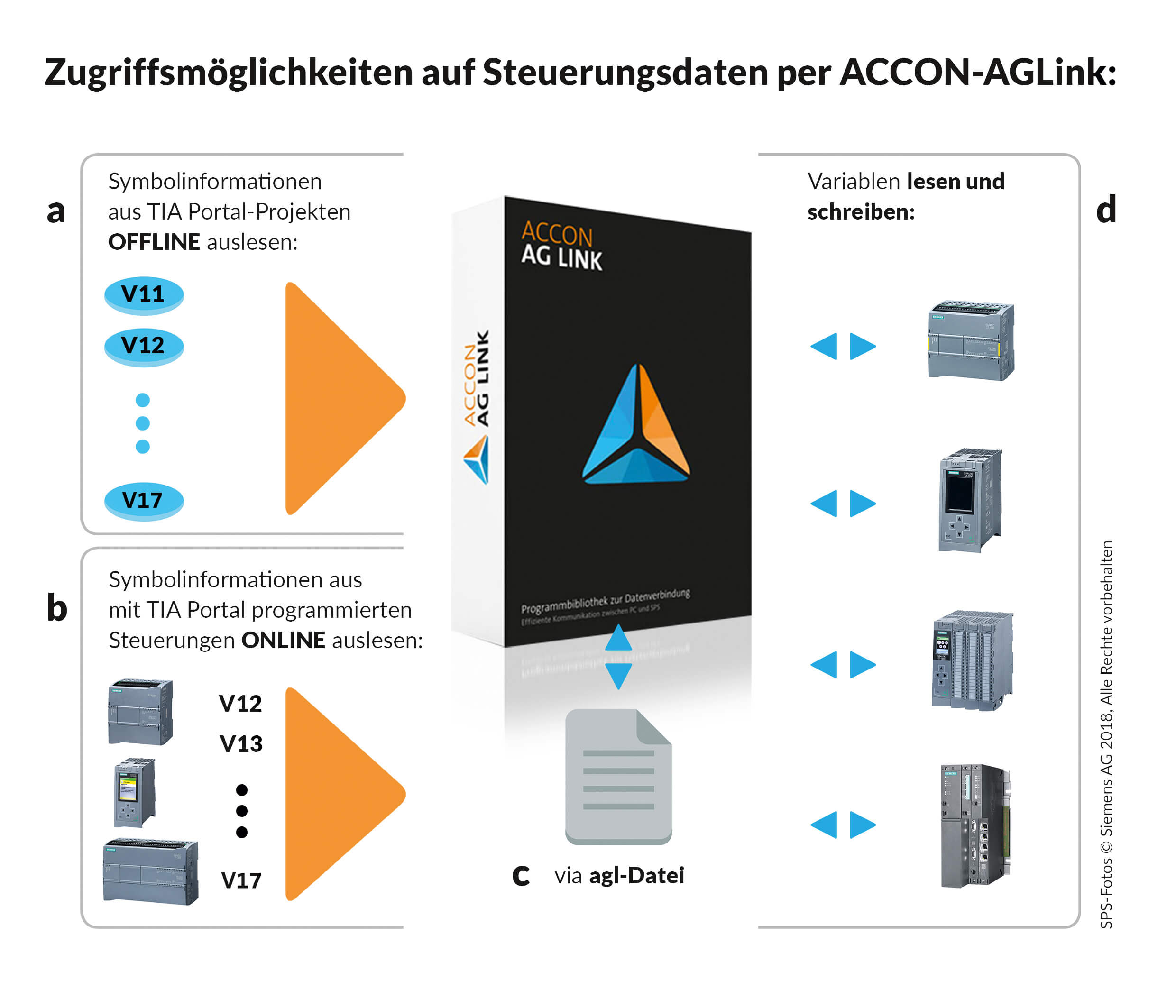

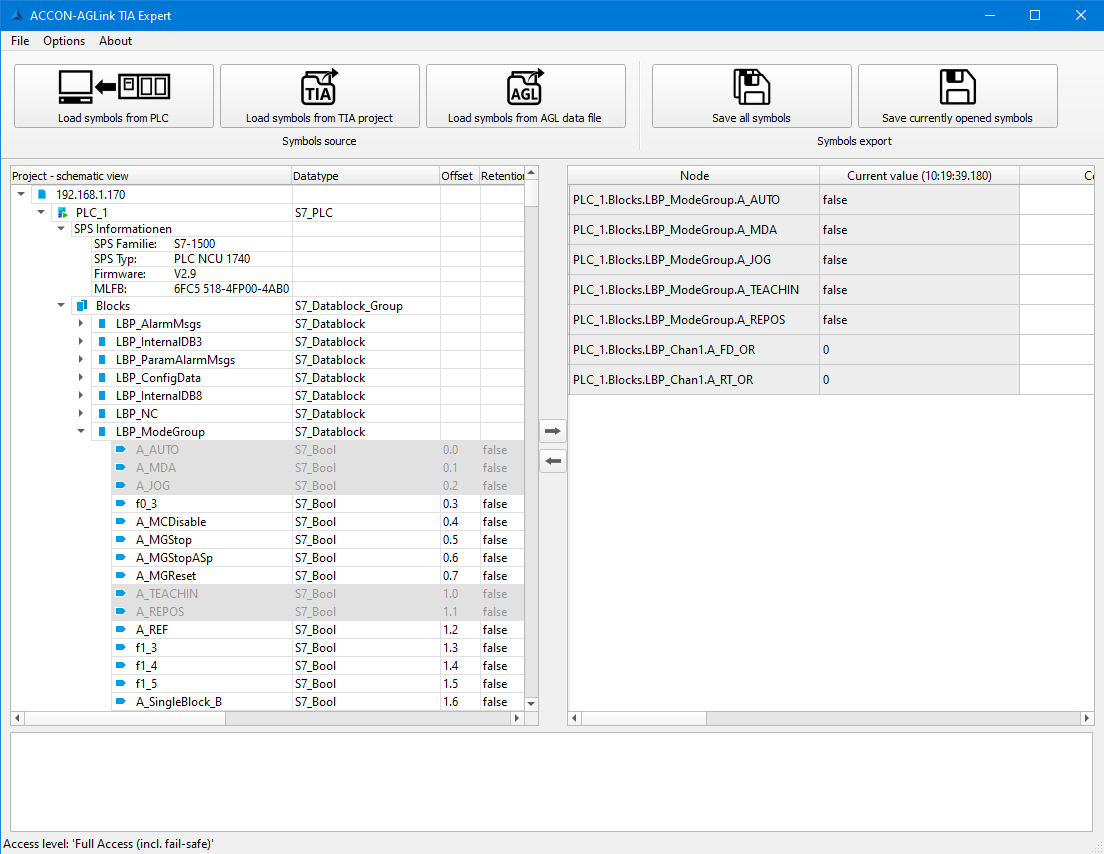

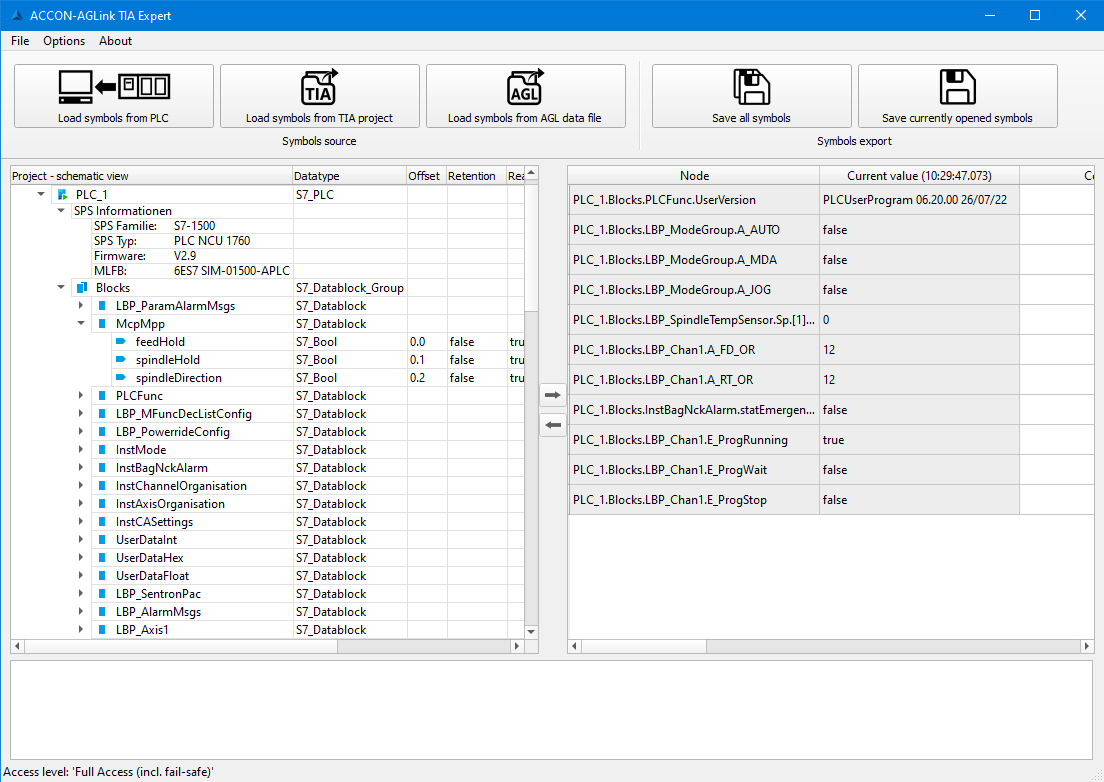

- TIA Portal support: symbol import, online and offline access

- Available for Windows, Windows CE, Linux, Linux Embedded, others on request

€0.00*

The fast and flexible communication library

Conventional PLCs are often the standard solution for solving automation tasks. PCs and servers are the first choice for control systems with an increased computing effort or large data collectives. The connection of the two systems is the task of ACCON AGLink. The communication library ACCON AGLink ensures a smooth data exchange between PC and PLC. Self-created PC programs can thus easily access a wide variety of controllers.

The existing software variety is a challenge for a networked workflow in automation and control technology. Automation applications such as control, monitoring, visualization and archiving are only possible through access to the process data of the controllers. For this, the applications must speak the same "language" as the controllers - in other words, they must master their protocols. ACCON AGLink was developed and optimized exactly for this communication. No matter if you want to access the different data areas (D, I, Q, M, T, C, P), read out the diagnostic buffer of a S7 controller or synchronize the PLC time with the PC time, ACCON AGLink provides you with the appropriate ready-to-use functions. For further simplification ACCON AGLink contains many conversion functions to convert PLC data types to PC data types.

Connecting your controller to ACCON AGLink

ACCON AGLink can be used with different controllers and communication paths, on different operating systems and with different programming languages. Should the connection you require to your controller not yet be supported, then contact us!

Access to a wide range of controllers and PLCs

ACCON AGLink is independent from the used controller hardware: No matter which controller hardware you want to access, with ACCON AGLink you don't have to care about the details. You are even able to access an old S5 or a new S7-1200 without any changes to your source code or application. With ACCON AGLink the access to the following PLCs is open to you:

- S7-200, S7-1200, S7-1500, S7-300, S7-400, S7-400H

- S7-compatible PLCs, e.g. Vipa, Saia, Berthel

- LOGO! 0BA7, LOGO! 0BA8

- SINUMERIK ONE, Create MyVirtual Machine, SINUMERIK 840D sl, 840D pl, 810D pl

- MicroMaster and SINAMICS

- S5

- Devices with 3964/3964R protocol

- Devices with RK512 protocol

- Devices with RFC1006 protocol

- Software Controllers S7-1505S and S7-1507S

- PLC Simulation SIMATIC S7-PLCSIM Advanced

Controller access independent of the communication path

In addition, ACCON AGLink is independent of the communication path used: The most different controller generations and PLC types support the most different communication paths - ACCON AGLink as well (inlcuding Secure Communication). The following communication options are available:

- S7-TCP/IP for S7 via 243-1, 343-1, 443-1, PN- and IE-CPUs (also S7-1200)

- MPI via ACCON MPI Adapter USB, ACCON MPI Adapter RS-232, ACCON MPI/TS Adapter, ACCON NetLink PRO compact, ACCON NetLink PRO, ACCON NetLink WLAN, ACCON NetLink USB compact, ACCON NetLink USB, ACCON NetLink S7, Siemens PROFIBUS CP, PROFIBUS cards from Softing and Hilscher

- PROFIBUS via ACCON NetLink PRO compact, ACCON NetLink PRO, ACCON NetLink WLAN, ACCON NetLink USB compact, ACCON NetLink USB, ACCON NetLink S7, Siemens PROFIBUS CP, PROFIBUS cards from Softing and Hilscher

- PPI via ACCON PPI Kabel, ACCON NetLink PRO compact, ACCON NetLink PRO, ACCON NetLink WLAN, ACCON NetLink USB compact, ACCON NetLink USB, ACCON NetLink S7, Siemens-PROFIBUS-CP, PROFIBUS cards from Softing and Hilscher

- S5-TCP/IP for S5 via CP 1430 TCP, Inat S5-TCP/IP 100, Vipa CP 143 TCP/IP, ACCON S5 LAN

- AS511 via ACCON COM Cable, ACCON COM Cable USB, ACCON COM Cable IE, ACCON S5 LAN

- RK512 via serial interface

- 3964 and 3964R via serial interface

- S5-ISO (H1) via CP1430

- SINUMERIK ONE via TCP/IP

Controller communication from different operating systems

ACCON AGLink is also independent of the operating system used. You want to write your application independent of the operating system? Then you have chosen the right communication library with ACCON AGLink. The change from a normal desktop application to a WinCE panel application often only requires a new compilation for the target system. ACCON AGLink is available for the following operating systems:

- Windows XP, Server 2008R2, 7, 8.1, Server 2012R2, 10, Server 2016

- Windows CE (as of version 4)

- Linux

- Linux Embedded

- Raspberry Pi

Programming languages for controller access according to your needs

Finally, ACCON AGLink is also independent of the programming language used: whether you have your preferred programming language or choose your programming language according to the project requirements, ACCON AGLink supports a wide range of development environments. You have the free choice from the following list:

- Microsoft Visual C/C++, Microsoft Visual Basic, Microsoft C#, Microsoft VB.net

- Borland Delphi, C++ Builder

- Codegear Delphi, C++ Builder

- Embarcadero Delphi, Delphi Prism, C++ Builder

- LabVIEW

- Java (not all functions covered)

- All languages that can use a Win32 or a WinCE DLL

- Gcc under Linux

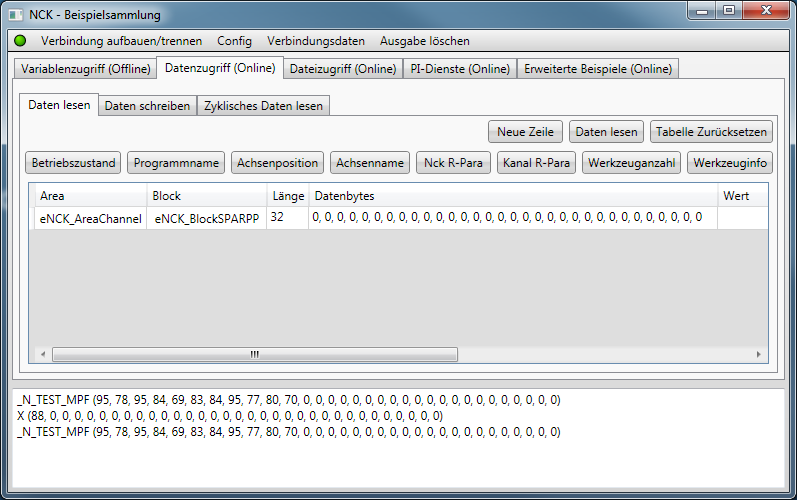

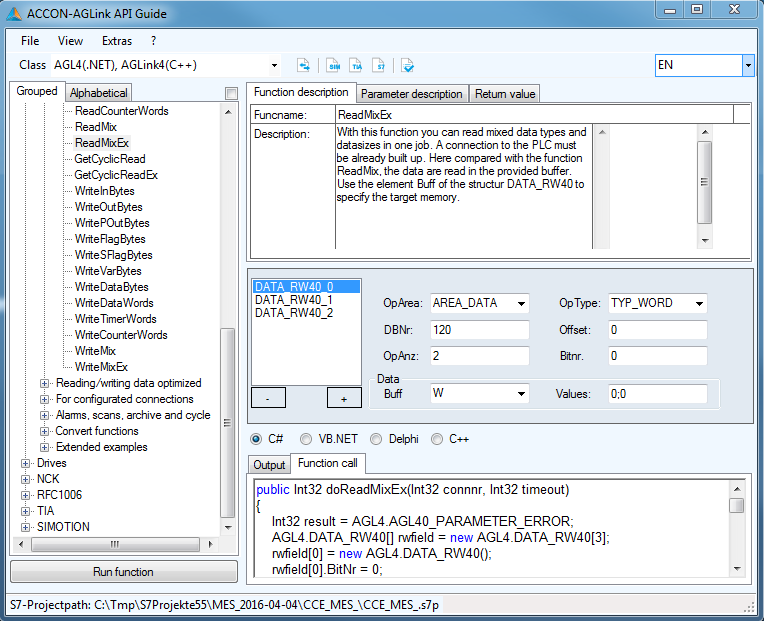

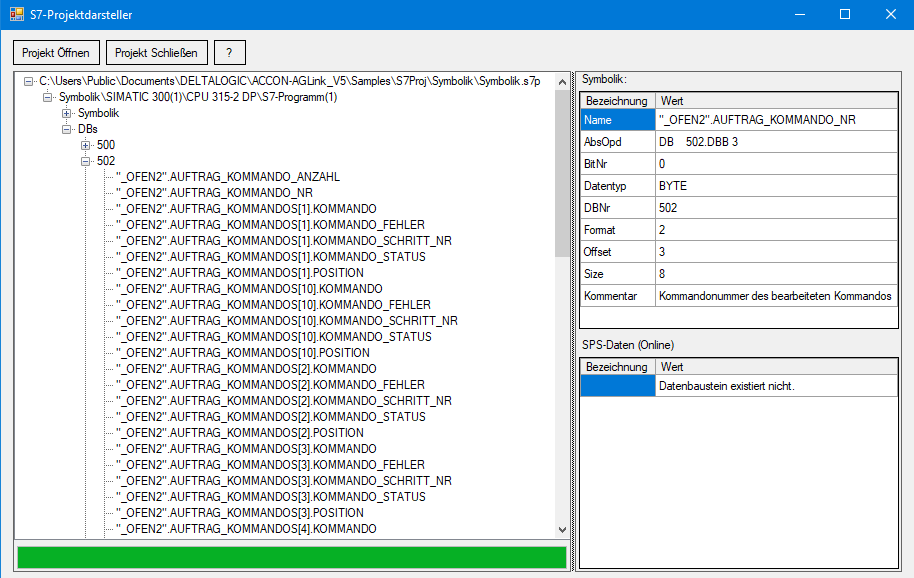

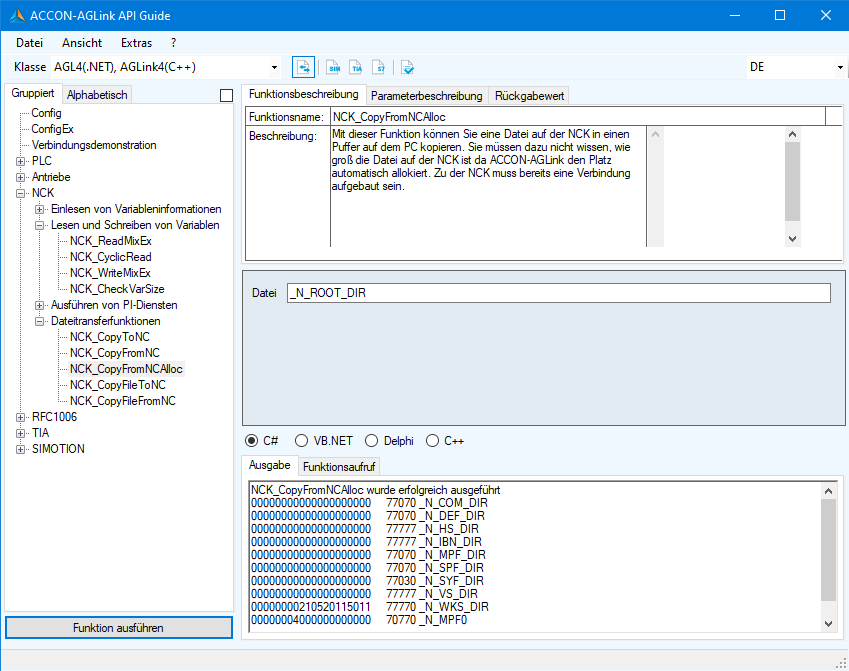

Faster development with included sample programs

The scope of delivery of ACCON AGLink includes sample programs for most programming languages. But this was not enough for us. Therefore we have developed the API-Guide (API = Application Programming Interface) for you. With this software you can not only execute and test every single function of ACCON AGLink directly and interactively, but you can also view the source code for it in C#, VB.net, C++, Delphi and Java. Your input is converted directly into the program code. You can then immediately copy and paste this into your development environment. You cannot develop the communication part any faster. ACCON AGLink can also directly access the symbols used in the PLC project. You want to select the operands in your application from the symbols of the used PLC project? You don't want to remember "M 10.0" and prefer to use "Door contact rear"? Very good, because this eliminates a potential source of error.

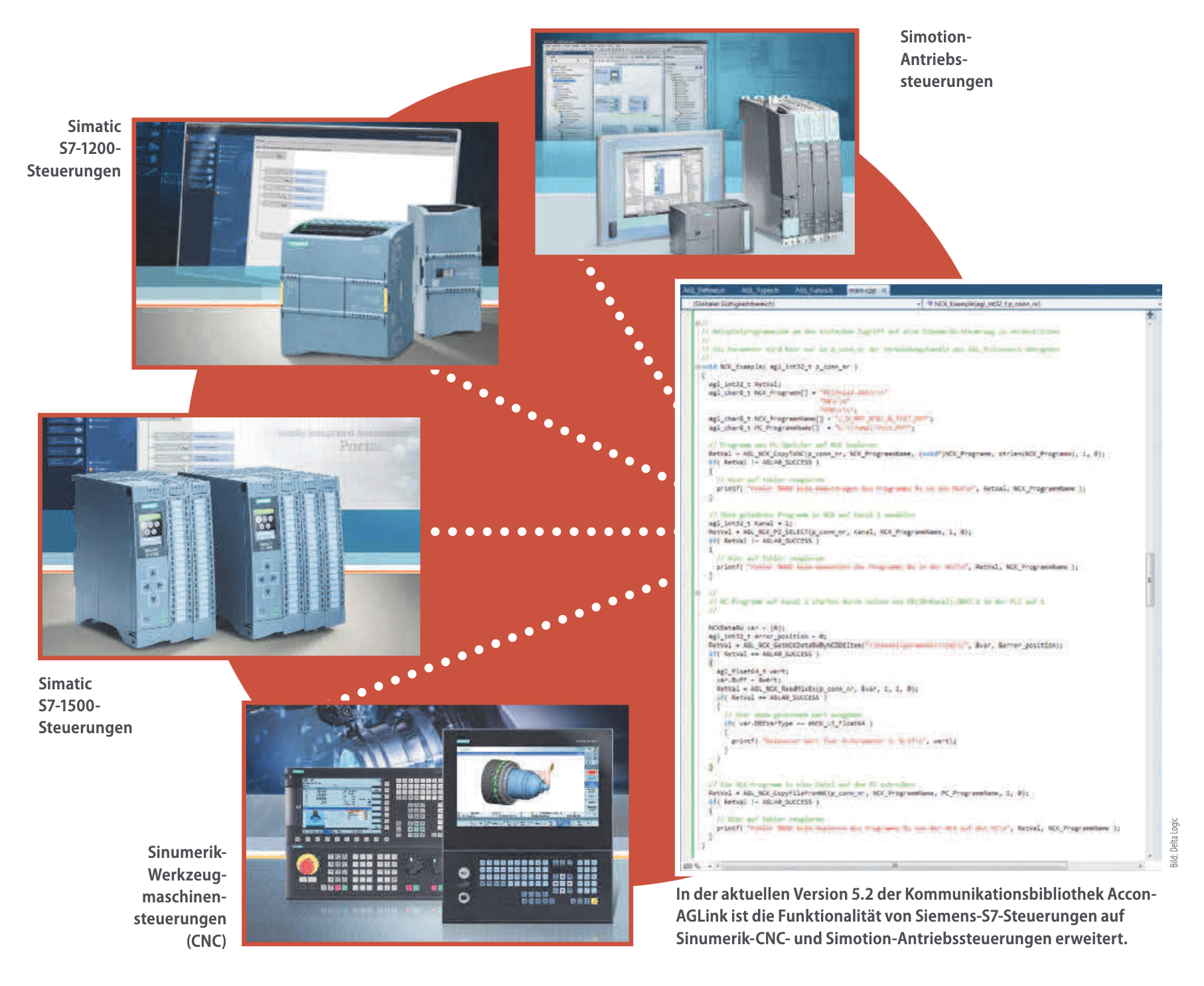

Access to machine tool controllers with ACCON AGLink

With ACCON AGLink you can also communicate with your CNC machine tool controller. For example, you can perform the following activities using the SINUMERIK AddOn:

- Determine utilization and availability of the CNC machines

- Monitor and record machine data such as operating mode, torques, power consumption, axis positions

- Display running NC program, number of parts produced and access level

- Access tool data such as magazine, tool offset data, tool monitoring data

- Read R-parameters, override, number of pending alarms

- Read information for preventive maintenance

- Monitoring (dashboard) of the machine, e.g. machine status, program status, cycle time, number of pieces, operating hours, OEE

Event-controlled communication with the PLC

As a special feature, ACCON AGLink offers the possibility to react event-driven to PLC telegrams to avoid having to start constant queries. BRECEIVE, URECEIVE, the complete alarm and acknowledgement handling as well as the operating state transition messages are available with ACCON AGLink.

Or do you only want to have certain values sent cyclically by the PLC without having to ask for them each time? We have already implemented these functions for you as well. Even complex control systems with different network technologies are no longer a problem with ACCON AGLink, since you can simply use the routing connections (e.g. from Ethernet to PROFIBUS) of the S7 controllers. And this, of course, without having to change a line of your program. Do you want to access more than one controller at the same time? The quantity structure of ACCON AGLink leaves nothing to be desired: Up to 256 communication devices with up to 16 PLCs each should suffice for any case. Of course, the devices can be different - even parallel access to different controller generations is easily feasible.

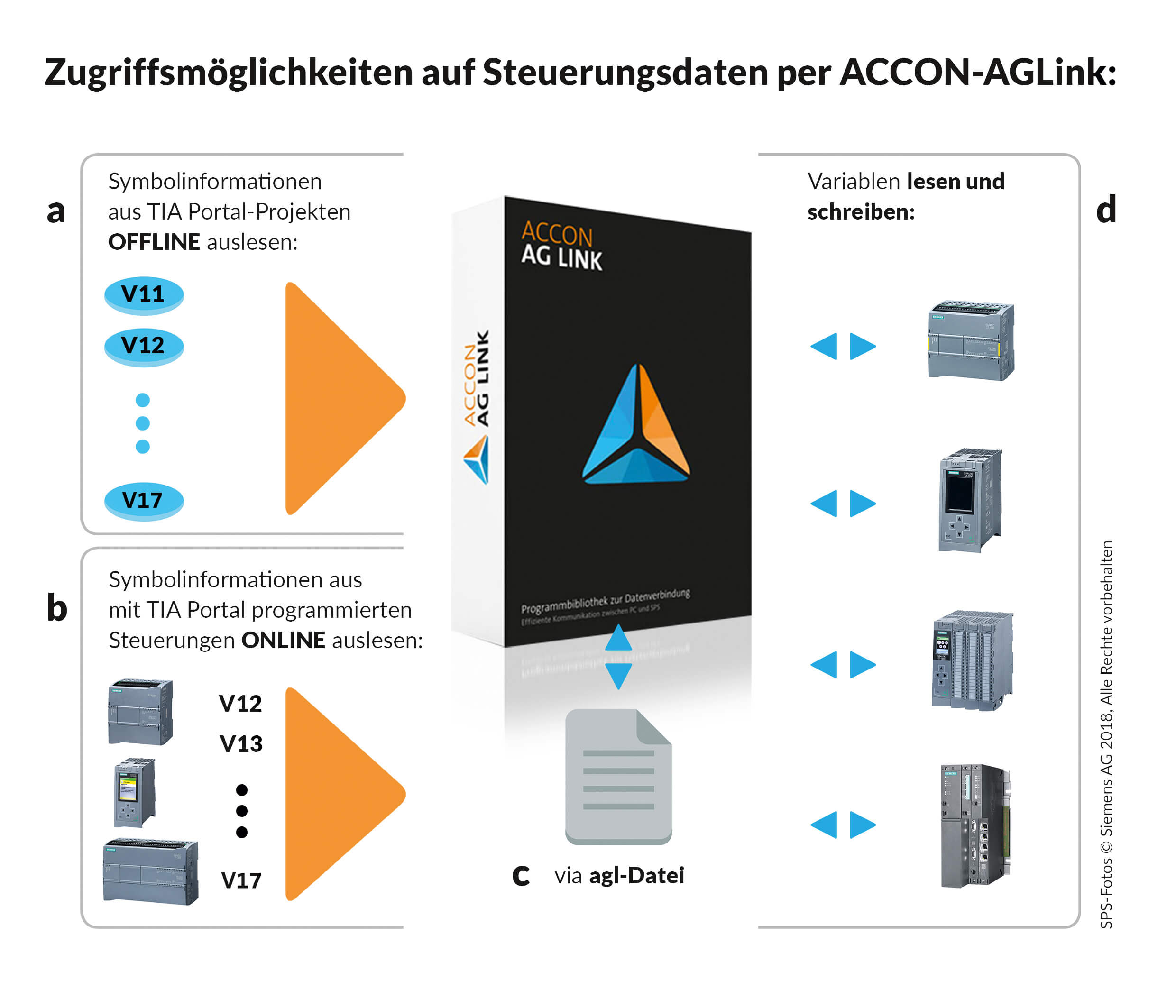

Access symbolic data and optimized block access

With ACCON AGLink you can access the symbol data in the following programs:

- S7-300 and S7-400 programs

ACCON AGLink supports the S7-1200/S7-1500 also with optimized block access and masters the import of symbols directly from the TIA Portal of the versions 12, 13, 14, 15, 15.1, 16, 17, 18 and 19 (since version 6.0.2.0).

Different single licenses to suit your requirements

The software ACCON AGLink is available as single license or as developer license. The ACCON AGLink single license always includes all available ACCON AGLink modules. It is available in three different variants: Classic, TIA and Pro. The single license must be purchased for each PC on which ACCON AGLink is used. You do not need to worry about the communication hardware or controller to be used, you always have the complete package with the ACCON AGLink single license according to the selected license scope:

- Single license Classic: contains all modules available for the operating system, except the TIA modules, the SINUMERIK AddOn and S5-ISO (H1)

- Single license TIA: contains all modules available for the operating system, except the two modules SINUMERIK AddOn and S5-ISO (H1)

- Single license Pro: includes all modules available for the operating system

Developer licenses for more runtime licenses and maintenance contracts

Alternatively, you can also purchase the developer license. It can consist of any combination of the available ACCON AGLink modules. Each developer needs his own license of ACCON AGLink. Subject to the license terms, the developer license includes an unlimited number of runtime licenses.

Additionally a maintenance contract is available for the developer license. It consists of the Software Update Service (SUS) and the Premium Support. Within the scope of the SUS you will receive all updates of ACCON AGLink promptly via e-mail during the term of your maintenance contract. This way you are always up-to-date even in case of firmware changes or new CPU types.

Notes on ACCON AGLink developer licenses

The module ACCON AGLink SINUMERIK AddOn additionally requires an ACCON AGLink communication module that supports the desired SINUMERIK controller.

The module ACCON AGLink S7-TCP/IP TIA additionally requires the module ACCON AGLink SymbolikPro TIA.

The module ACCON AGLink S7-RedConn requires at least one additional ACCON AGLink communication module.

For the modules ACCON AGLink S7-TCP/IP TIA and ACCON AGLink S7-SymbolikPro TIA a maintenance contract is mandatory.

Technical highlights

- Supports controller types S7-200, S7-1200, S7-1500, S7-300, S7-400, S7-400H, LOGO! 0BA7, LOGO! 0BA8 and S5

- Supports machine tool controllers SINUMERIK ONE, Create MyVirtual Machine, SINUMERIK 840D sl, 840D pl, 810D pl

- Supports routed, configured and redundant connections and Secure Communication

- Communication via MPI, PROFIBUS, PPI, TCP/IP and RK512/3964(R)

- Change of communication path possible without program change

- Uniform software for all controller types and for all supported operating systems

- Extensive functionality for writing and reading process data

- Extensive comfort functions

- Access to S7 symbol data (with module SymbolikPro)

- Available for Windows, Windows CE, Linux, Linux Embedded, Solaris, OS9000 and VxWorks

- Supports all common programming languages via DLL or shared object

- Maintenance contract available (Note: for TIA modules a maintenance contract is mandatory)

- Supports S7-1200 and S7-1500 with symbolic access via TCP/IP incl. TIA project import (with module SymbolikPro TIA)

- Supports controller types: Software Controller S7-1505S and S7-1507S

- Supports PLC simulation SIMATIC S7-PLCSIM Advanced

- TIA Portal is supported, in online as well as offline access

- Also FW 2.9.x and 3.0.x for S7-1500 as well as FW 4.5 and 4.6 for S7-1200 is supported

- Access to PLCs (S7-1200/1500) with access protection: Even with 'No Access' reading and writing of variables is possible through password entry.

- Project upload of CPUs with parameterized protection level is possible with password input. The current protection level can be queried (S7-1200/1500).

- Alarms of S7-1500 are supported

- PLC time can be read and set (S7-1200/1500)

- Operating status (run/stop) can be read and set (S7-1200/1500)

- .Net Core supports Windows and Linux

- S5-ISO (H1) for Windows and Linux

- New since version 6.0: Secure Communication, SINUMERIK ONE, Create MyVirtual Machine as well as a new module: SINUMERIK AddOn

- For SINUMERIK: No change to the CNC program necessary, no Siemens license required

Features of the SINUMERIK AddOn module

- Access to over 4000 NC variables

- Access to user data (GUD)

- Comfortable browsing of variables and GUDs

- Optimized variable access to avoid protocol errors due to invalid query order

| Supported perating systems |

Windows XP, 2008 R2, 7, 8.1, 2012 R2, 10, 11, Server 2016, 2022 |

| Supported PLCs | S5, S7-200, S7-1200, S7-1500, S7-300, S7-400, S7-400H (S7-300/400-compatible, e.g. Vipa, Saia, Berthel), LOGO! 0BA7, LOGO! 0BA8, devices with 3964/3964R protocol, devices with RK512 protocol, devices with RFC1006 protocol, software controller S7-1505S and S7-1507S, PLC simulation SIMATIC S7-PLCSIM Advanced, SINUMERIK ONE, Create MyVirtual Machine, SINUMERIK 840D sl, 840D pl and 810D pl |

Supported communication channels

The following table shows which communication path is supported by which ACCON AGLink communication hardware.

| PLC interface | PC interface | |||

| TCP/IP | USB | RS-232 | Siemens CP | |

| S7-300/400/400H via MPI | ACCON NetLink PRO compact ACCON NetLink PRO ACCON NetLink WLAN ACCON NetLink S7 |

ACCON NetLink USB compact ACCON NetLink USB ACCON MPI Adapter USB |

ACCON MPI Adapter RS-232 ACCON MPI/TS Adapter |

+ |

| S7-300/400/400H via PROFIBUS | ACCON NetLink PRO compact ACCON NetLink PRO ACCON NetLink WLAN ACCON NetLink S7 |

ACCON NetLink USB compact ACCON NetLink USB |

- | + |

| S7-300/400/400H via TCP/IP (PN/IE) | + | - | - | + |

| S7-300/400/400H via Modem | - | - | ACCON MPI/PROFIBUS Modem ACCON MPI Modem ACCON MPI/TS Adapter Alarm Modem |

- |

| S7-200 via PPI | ACCON NetLink PRO compact ACCON NetLink PRO ACCON NetLink WLAN ACCON NetLink S7 |

ACCON NetLink USB compact ACCON NetLink USB |

ACCON PPI Adapter | + |

| S7-200 via TCP/IP | + | - | - | + |

| S7-1200 via TCP/IP | + | - | - | + |

| S7-1500 via TCP/IP | + | - | - | + |

| LOGO! 0BA7, LOGO! 0BA8 | + | - | - | - |

| SINUMERIK1 via PROFIBUS | ACCON NetLink PRO compact ACCON NetLink PRO ACCON NetLink WLAN ACCON NetLink S7 |

ACCON NetLink USB compact ACCON NetLink USB |

- | - |

| SINUMERIK1 via TCP/IP | + | - | - | - |

| SINUMERIK ONE via TCP/IP | + | - | - | - |

| Devices2 via PROFIBUS | ACCON NetLink PRO compact ACCON NetLink PRO ACCON NetLink WLAN ACCON NetLink S7 |

ACCON NetLink USB compact ACCON NetLink USB |

- | - |

| Devices2 via TCP/IP | + | - | - | - |

| S5 via PG bushing (AS511) | ACCON S5 LAN ACCON COM Cable IE |

ACCON COM Cable USB | ACCON COM Cable ACCON COM Adapter |

- |

| S5 via TCP/IP | + | - | - | - |

| 3964/3964R/RK512 | - | - | + | - |

| RFC1006 | + | - | - | - |

+ Without adapter possible

- Not possible

1 SINUMERIK 840D pl, 840D sl, 810D pl

2 MicroMaster of SINAMICS

Available ACCON AGLink modules

ACCON AGLink has a modular structure. The following table shows which communication hardware can be used for which PLC interface depending on the ACCON AGLink module.

| ACCON AGLink module | Supported communication hardware | Supported PLC interface |

| ACCON AGLink S7-serial | ACCON MPI Adapter RS-232 ACCON MPI Adapter USB ACCON PPI Adapter |

MPI PPI |

| ACCON AGLink S7-PB | ACCON NetLink PRO compact ACCON NetLink PRO ACCON NetLink WLAN ACCON NetLink S7 ACCON NetLink USB compact ACCON NetLink USB Hilscher PROFIBUS cards Softing PROFIBUS cards |

MPI PROFIBUS PPI |

| ACCON AGLink S7-TCP/IP | Network interface at PC | CP 243-1 CP 343-1 CP 443-1 PN and IE CPUs (even S7-1200) |

| ACCON AGLink S7-PC/CP | Siemens CPs via the Siemens device driver in Set PG/PC interface (CP 5511, CP 5512, CP 5611, CP 5613, CP 5614, CP 5711, CP 1613) and PC adapter USB | MPI PROFIBUS PPI IE |

| ACCON AGLink S7-RedConn | Only required for redundancy. At least one additional ACCON AGLink communication module is required for communication. | Depending on the communication module |

| ACCON AGLink S5-AS511 | ACCON COM Cable ACCON COM Cable USB ACCON S5 LAN ACCON COM Cable IE |

PG socket of the S5 |

| ACCON AGLink S5-TCP/IP | Network interface at PC | ACCON S5 LAN CP 1430 TCP Inat S5-TCP/IP 100 Vipa CP 143 TCP/IP |

| ACCON AGLink S5-ISO (H1) | Network interface at PC with packet driver | CP 1430 |

| ACCON AGLink RK512 | Serial cable | e.g. CP 524 or CP 525 |

| ACCON AGLink RFC1006 | Network interface at PC | Ethernet |

| ACCON AGLink S7-SymbolikPro | None, allows access to the symbolic operands of an S7-300 or S7-400 project | - |

| ACCON AGLink S7-SINUMERIK AddOn | Requires an ACCON AGLink communication module that supports the desired SINUMERIK controller | See corresponding ACCON AGLink communication module |

Direct data access

February 2018

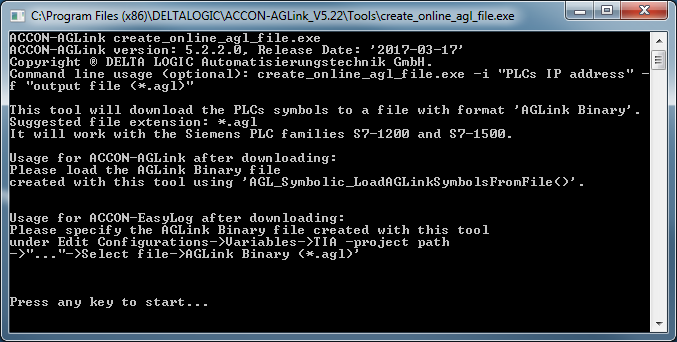

PC-PLC communication: With the help of the ACCON-AGLink communication library, users can also access data from the S7-1200 and S7-1500 controllers outside the Siemens product world. With the current version of the library, this is also possible directly online from the controllers.

Industrial App facilitates mobile HMI

May 2017

In times of Industry 4.0 and digitalization, the requirements for concepts for operating and monitoring machines and systems are changing. Mobile human machine interfaces (HMI) are making their way into the industrial environment. For these, Monkey Works offers a development environment to easily and quickly generate apps for various end devices. To enable the HMIs to communicate directly with Siemens controllers, the company has integrated the ACCON AGLink communication library from Delta Logic into its HMI Suite.

Online data access to Simatic S7 controllers

March 2017

The software update version 5.2 of the communication library ACCON AGLink from DELTA LOGIC Automatisierungstechnik enables developers to access outside the Siemens product world not only symbolic information from TIA Portal projects, but also directly data from Siemens S7 controllers with symbolic addressing. The advantage: The project data is always up-to-date.

Simatic S7 communication without alternative

July 2016

With the modernization of the palletizing system, the IT specialists at the Iglo plant in Reken were faced with the challenge of implementing a high-performance data transfer between the Oracle plant database and the new Simatic S7-1500 controllers. With ACCON AGLink from DELTA LOGIC, communication between the two software worlds could be realized without compromising the performance of the controllers.

Precision for machine tools

September 2015

Precision is a top priority in machine tool manufacturing. Accordingly, at the spindle manufacturer Kessler, every single motor spindle must undergo extensive quality assurance tests before delivery - an enormous challenge in terms of data handling between the central SQL database and the connected test benches.

Info exchange at the sawmill

September 2015

Machine builders and plant operators are often faced with the challenge of having a PC-based software and an S7 controller from Siemens communicate with each other. In order to be able to establish two-way communication between these different technical spheres, a special interface is required.

| Data sheet ACCON AGLink | ||

| Data_sheet_ACCON-AGLink.pdf | 802 KB | July 13, 2021 |

| Hoja_de_datos_ACCON-AGLink.pdf | 813 KB | July 13, 2021 |

|

ACCON AGLink 6.0.2.0 demo version with manual and examples 32/64-bit Windows Note: The setup is not executable under Windows XP. |

||

| SetupAcconAGLink_6020.zip | 264 MB | February 06, 2024 |

|

Demo version ACCON AGLink 6.0.2.0 with manual and examples for Linux |

||

| ACCON-AGLink-6.0.2.0-Linux-Install.zip | 46,6 MB | February 06, 2024 |

| Version history | ||

| History_ACCON-AGLink.txt | 148 KB | February 06, 2024 |

Archive

| ACCON AGLink 5.6.2.0 demo version with manual and examples 32/64-bit Windows | ||

| SetupAcconAGLink_5620.zip | 116 MB | July 07, 2021 |

| Demo version ACCON AGLink 5.6.2.0 with manual and examples for Linux | ||

| ACCON-AGLink-5.6.2.0-Linux-Install.zip | 44,3 MB | July 07, 2021 |

| ACCON AGLink 5.6.0.0 demo version with manual and examples 32/64-bit Windows | ||

| SetupAcconAGLink_5600.zip | 112 MB | December 10, 2019 |

| Demo version ACCON AGLink 5.6.0.0 with manual and examples for Linux | ||

| ACCON-AGLink-5.6.0.0-Linux-Install.zip | 44,8 MB | December 10, 2019 |

| ACCON AGLink 3.7 demo version with manual and examples 32-bit Windows | ||

| ACCON-AGLink_37.zip | 22.4 MB | March 05, 2008 |

| CPU data update for access to S7 projects, can be used with ACCON AGLink S7-SymbolikPro, ACCON-S7-Backup, S7-Power-Tools and PLC-Analyser AutoSPY | ||

| PGS7Data.zip | 7 KB | May 05, 2016 |

Modules, licenses and updates

Can I access S7-1200/1500 controllers with ACCON AGLink?

Yes, this is possible. If you use an older version of ACCON AGLink (V4), you have to consider the corresponding application notes.

Which AGLink modules are required for read/write access to symbolic variables on an S7-1200/1500?

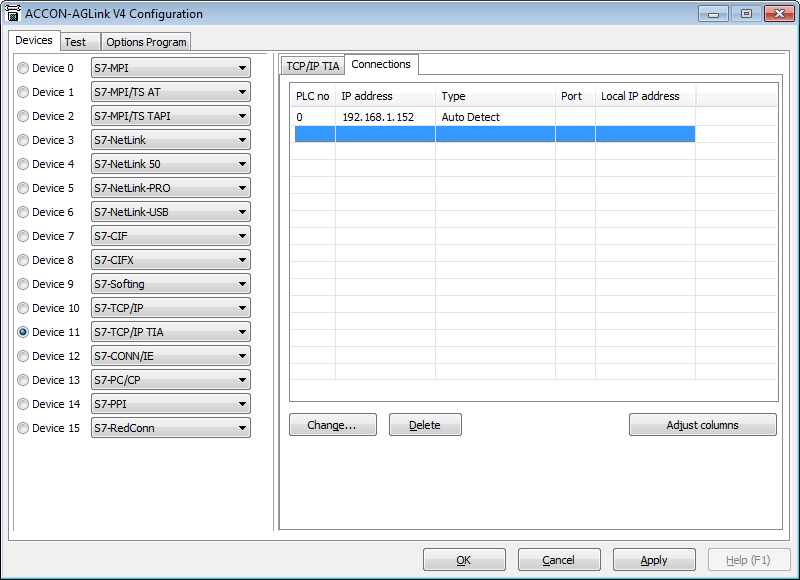

Two modules are required for this: S7-SymbolikPro TIA and S7 TCP/IP TIA. S7-SymbolikPro TIA is used for the symbol resolution. The S7 TCP/IP TIA module uses this symbol information from S7-SymbolikPro TIA and can thus access the data of the S7-1200/1500.

Do I have to change my program code if I want to use an additional module of ACCON AGLink?

No, you don't have to. Because of the universal software interface of ACCON AGLink it is possible to simply install the new DLL or shared object and set the new parameters with the program AGLink40_Config.EXE. After that the new hardware can be used immediately.

Where are the configuration files of ACCON AGLink stored?

ACCON AGLink stores the configuration files under the following path: "C:\Users\Public\Documents\DELTALOGIC\ACCON-AGLink_V5"

I have purchased an update for my developer license but have not received a license key. What do I need to do?

Please use the license key from your previous version.

Why does the message "This is an evaluation copy ..." appear even though I am using a licensed AGLink40.dll?

Probably there is a loaded demo version of AGLink40.dll in your application directory. With the AGLink functions GetClientName, GetSerialNumber and GetVersionEx you can determine which DLL is loaded.

Alternatively you can search for "AGLink40.dll" on the PC and rename all others as a test. It could also be that other software vendors which are using the AGLink40.dll as well have set a priority in the global environment variable PATH. The problem can be avoided by loading the AGLink40.dll dynamically (with path specification).

Connections, read and write

I cannot use the PG/PC interface on a 64-bit system with ACCON AGLink S7-PC/CP. How can I solve the problem?

The latest version of ACCON AGLink works with the PG/PC interface on a 64-bit system. Please remember that a 32-bit application is compiled anyway. In reality the PG/PC interface can only be used with 32-bit applications.

In the connection configuration: What do AG number, rack and slot mean?

For TCP/IP connections, the AG number is a virtual ID. The assignment of the IP addresses takes place via this ID. At MPI connections the AG number is the bus address of the S7-CPU. Via the rack and slot number the location of the S7-CPU is indicated.

Why is S7 data that I write via AGLink apparently not changed correctly in the S7?

Please check whether the operand that is written is also used as Out or In/Out parameter in a block call. In this case the write operation does not return an error and the operand is overwritten most sporadically by the PLC itself when the function is exited.

Remedy: Store the operands that you write in a separate DB or flag and then copy the data to the actual DB via handshake.

I have updated TIA Portal to V14. Now I can not read out any variables. Why?

Possibly your AGLink version does not support V14. TIA Portal V14 is supported only since ACCON AGLink version 5.2.

"The training at DELTA LOGIC on AGLink was just fantastic! My task is to read NCK variables from a controller, which is a very complex topic. In the training I received valuable information and documents. The tools API Guide (for AGLink) and another one I got for free in the training, which I'm sure are not available anywhere else like this, are just priceless. It makes the task easy and fun.

The training is exactly targeted to the participant and all open questions are answered. I can now easily implement my tasks. Very best thanks again for this!"

"Big compliments go to the very competent support and the great communication library, the ACCON AGLink from DELTA LOGIC."

"I would like to take this opportunity to thank DELTA LOGIC for the excellent support! The support from your company in this situation was really very good and I am glad that we chose your company, the AGLink components and also the maintenance contract at that time."

"We are very satisfied with ACCON AGLink. Everything has worked wonderfully. ACCON AGLink provides good examples and the connection is also really easy."

"The ACCON AGLink programming library and DELTA LOGIC in general are predestined to be recommended."

"For the first larger plant control, which could not be realized with a Siemens control for various reasons, we have now used ACCON AGLink for the communication between PC and Siemens PLC. For this new development we were very convinced of ACCON AGLink, had only good experiences with it and also got very positive feedback from the PLC programmer involved. Since your products provide many more possibilities that are currently unused by us, further application possibilities will certainly open up in the future, which we will then gladly take advantage of."

"The other suppliers didn't have a solution. You would have had to deal with an additional PLC somehow. With ACCON AGLink, we really have the deluxe solution. That is more than expected."